A “cargo worthy” container is not a guarantee against water damage; the true risk lies in atmospheric condensation and systemic failures that standard inspections miss.

- The container’s ownership model (Shipper vs. Carrier) directly dictates your control over quality and maintenance history.

- Improper weight distribution is a leading cause of structural failure, while transloading creates severe atmospheric shock, threatening sensitive electronics.

Recommendation: Shift from a point-in-time visual check to a lifecycle risk assessment, integrating IoT monitoring and strict protocols for loading and intermodal transfers.

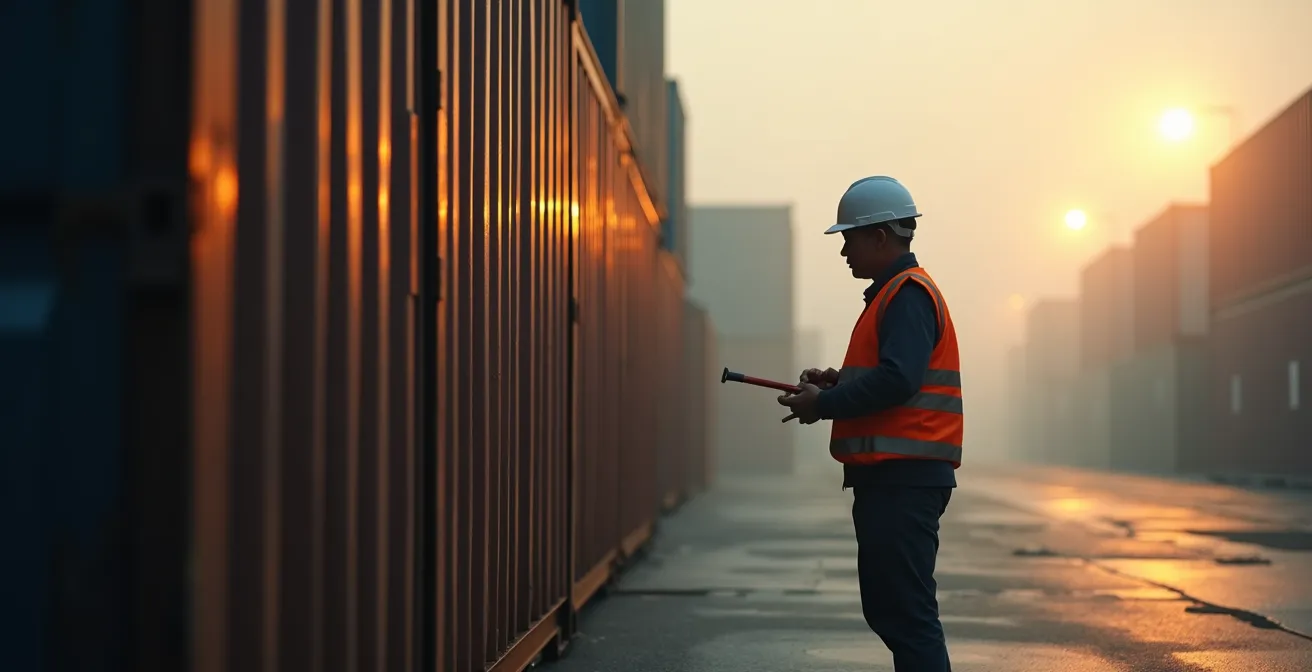

For any warehouse receiving team or loading supervisor, the integrity of an ISO container is paramount. You perform the standard checks: you look for holes with a light test, inspect the door gaskets for tears, and glance at the CSC plate. If it passes, you assume your high-value cargo is safe. This assumption can be a multi-thousand-dollar mistake. The most catastrophic water damage doesn’t come from obvious holes, but from an invisible process called “container sweat”—condensation forming inside a sealed unit due to temperature fluctuations during transit.

Common wisdom focuses on the container as a static box. But this view is dangerously incomplete. A container is a dynamic environment, subject to immense physical and atmospheric stress. A truly professional inspection protocol looks beyond the visible and assesses the entire system: the container’s ownership history, its intended route, the physics of its load, and the risks at every transfer point. It acknowledges that a container deemed legally “cargo worthy” might be completely unsuitable for a food-grade or electronics shipment.

This guide abandons the superficial checklist. Instead, it provides a certified inspector’s framework for identifying the hidden vulnerabilities that lead to moisture damage. We will deconstruct the factors that truly determine a container’s fitness for purpose, moving from strategic ownership decisions to tactical deployment of technology. By understanding the ‘why’ behind container failure, you can build a resilient inspection and loading process that genuinely protects your high-value assets.

To navigate these advanced concepts effectively, this article is structured to build your expertise from the ground up. The following summary outlines the key areas we will cover, from foundational principles to advanced risk mitigation strategies.

Summary: An Advanced Inspection Protocol for ISO Containers

- Why a “cargo worthy” container might still ruin your food-grade shipment?

- How to decide between Shipper Owned Containers (SOC) and Carrier Owned (COC)?

- Leasing vs One-way use: Which is better for shipments to remote destinations?

- The weight distribution mistake that causes containers to buckle during lifting

- How to upgrade a standard fleet with IoT trackers for under $50 per unit?

- How to mitigate transloading risks when moving fragile electronics from ocean to rail?

- How to deploy IoT sensors on pallets to eliminate lost inventory?

- How to move heavy bulk commodities safely across unstable geopolitical regions?

Why a “Cargo Worthy” Container Might Still Ruin Your Food-Grade Shipment?

The term “cargo worthy” is a technical standard, not a promise of quality for sensitive goods. It primarily certifies that a container is structurally sound enough for transport and meets basic Wind and Water Tight (WWT) criteria. However, it fails to account for the primary cause of non-obvious water damage: container sweat. This phenomenon of internal condensation is a significant threat, as recent marine insurance data reveals that up to 10% of global ocean container shipments experience moisture-related damage.

Condensation occurs due to rapid temperature and humidity changes during transit. As a container moves from a warm, humid climate to a cooler one, the air inside can no longer hold its moisture. This water vapor condenses on the container’s ceiling and walls, “raining” down onto the cargo. This is particularly damaging for food-grade products, where moisture can lead to mold, spoilage, and packaging failure. As noted in studies on Asia-Pacific routes, the extreme heat and humidity during monsoon seasons create a perfect storm for severe condensation, compromising shipments even in perfectly sealed containers.

Therefore, an inspection for a food-grade shipment must go beyond structural checks. It requires assessing the container’s history for carrying odorous cargo, ensuring it’s free of residues, and planning for moisture control with desiccants or liners. A container that previously carried chemicals, for instance, could be “cargo worthy” but would contaminate a food shipment. The focus must shift from “is it sealed?” to “is the internal environment safe for my specific product?”.

How to Decide Between Shipper Owned Containers (SOC) and Carrier Owned (COC)?

One of the most strategic decisions impacting cargo safety is not about the physical container, but its ownership model. Choosing between a Shipper Owned Container (SOC) and a Carrier Owned Container (COC) fundamentally alters your level of control over quality, maintenance, and risk. COCs are the default option, provided by the shipping line. While convenient, they present a significant unknown: you have no visibility into the container’s age, maintenance history, or prior cargoes. You receive what’s available, which could be an older, end-of-life unit with degraded seals and hidden structural weaknesses.

In contrast, an SOC grants you full control over the asset. You dictate the inspection protocol, maintain a complete service history, and can ensure the container is used exclusively for your specific type of cargo (e.g., only food-grade products). This is critical for high-value or sensitive goods where contamination or moisture ingress would be catastrophic. While SOCs require a higher upfront investment and management overhead, they significantly reduce risk exposure. The choice is a trade-off between lower upfront cost (COC) and lower long-term risk (SOC).

To make an informed decision, you must perform a risk assessment that considers the value of your cargo, the specific requirements of your trade lane, and the availability of quality inspection facilities. A formal analysis comparing these factors is not just recommended; it is a necessity for professional fleet management. The following matrix, based on an industry-standard risk assessment framework, provides a clear comparison.

| Factor | SOC (Shipper Owned) | COC (Carrier Owned) |

|---|---|---|

| Quality Control | Full control over inspection protocols | Subject to carrier’s variable standards |

| Maintenance History | Complete documented history available | Often opaque or unavailable |

| Container Age | Known and controlled | Unknown, potentially end-of-life units |

| Inspection Frequency | Owner-determined schedule | Carrier’s standard intervals |

| Cost Structure | Higher upfront, lower risk exposure | Lower upfront, higher risk exposure |

Your 5-Step SOC vs. COC Decision Framework

- Calculate Total Cost of Risk (TCR): Factor in potential cargo damage losses, not just freight costs, for both models.

- Assess Route-Specific Requirements: Determine if your cargo needs food-grade, pharma-grade, or other specialized container standards that a generic COC cannot guarantee.

- Evaluate Inspection Infrastructure: Confirm the availability of reliable inspection and repair facilities at your key origin and destination ports for managing an SOC fleet.

- Analyze Historical Damage Rates: Review your own data for specific trade lanes to see if damage correlates with the use of COCs.

- Negotiate Contractual Clauses: If using COCs, attempt to negotiate terms that set limits on container age and require proof of recent inspection.

Leasing vs One-Way Use: Which Is Better for Shipments to Remote Destinations?

When shipping to remote or low-traffic destinations, the choice between leasing a container and using it for a “one-way” trip introduces another layer of complexity. One-way use, where a shipper uses a container for a single journey and then returns it to a carrier’s depot at the destination, seems convenient. However, this convenience comes at the cost of quality control, especially in remote locations where the available container pool may be old or poorly maintained.

Leasing, particularly a long-term master lease, provides more control, similar to owning an SOC. It allows you to operate a consistent fleet of containers whose condition you know and manage. The challenge with remote destinations is the logistics of repositioning an empty leased container, which can be expensive. However, for high-value goods, this cost can be justified when weighed against the risk of using a substandard one-way container. A key part of this assessment involves understanding inspection regimes like the Approved Continuous Examination Program (ACEP). As noted by experts at Container Management Inc., ACEP links inspections to repair events. If a container in a remote location is not frequently damaged or repaired, it may go long intervals without a thorough examination, increasing hidden risks.

The core issue, as visualized above, is the lack of reliable infrastructure in many remote ports. Finding a certified inspector or a facility capable of performing proper repairs can be difficult. This elevates the risk of being forced to use a container that does not meet your standards. For one-way trips, you are at the mercy of the local supply. For leased units, you bear the cost of returning a potentially damaged container to a qualified repair depot. For critical shipments, a strategy of leasing newer, high-quality containers, even with the added repositioning cost, often proves to be the safer and more cost-effective choice in the long run.

The Weight Distribution Mistake That Causes Containers to Buckle During Lifting

While external water ingress is a major concern, an equally critical point of failure originates inside the container before it’s even sealed: improper weight distribution. A container’s strength is not uniform. It is designed to transfer its load through its four corner posts. When a load is concentrated in the center of the container, away from the side walls, it places immense stress on the floor and the underlying cross members. This is a common mistake that can lead to catastrophic failure during lifting.

During a lift by a crane or straddle carrier, a container with a centrally concentrated heavy load can literally buckle or “bow” downwards. This not only damages the cargo but also compromises the container’s structural integrity, potentially twisting the frame and breaking the hermetic seal of the doors. Even if the container doesn’t fail completely, the flexing can be enough to dislodge cargo, leading to damage from internal impacts. It is a critical safety issue, as ISO inspection data demonstrates that around 15% of container structural failures result from improper weight distribution.

To prevent this, loading supervisors must ensure that the cargo’s center of gravity is as close as possible to the container’s geometric center and that the weight is spread over the largest possible floor area. For heavy, dense items, this means using dunnage to distribute the load towards the side walls and away from the unsupported center. Verifying this is a key part of the pre-transport inspection. Professional testing facilities confirm that a container’s resilience depends on its ability to handle the extraordinary dynamic forces of transit. By failing to distribute weight correctly, loading teams are creating internal forces that the container was never designed to withstand, setting it up for failure from the inside out.

How to Upgrade a Standard Fleet with IoT Trackers for Under $50 Per Unit?

A physical inspection, no matter how thorough, only provides a snapshot of the container’s condition at one moment in time. It cannot tell you what happens during the weeks-long journey at sea. This is where Internet of Things (IoT) technology becomes a game-changer, transforming a standard container from a “black box” into a transparent, monitored environment. And contrary to common belief, this upgrade is surprisingly affordable.

For under $50 per unit, a container can be equipped with a suite of wireless sensors that provide real-time data on critical parameters. This investment offers a staggering return, as industry analysis shows that a one-time $50 sensor investment prevents an average loss of $15,000 per damaged shipment. The core of this upgrade includes:

- Humidity and Temperature Loggers: These are the most critical sensors. By setting alert thresholds (e.g., at 60-65% relative humidity), you can be notified of conditions that lead to container sweat, allowing for preemptive action or providing crucial data for an insurance claim.

- Accelerometer Sensors: These detect and record shock events. A significant impact could indicate mishandling during loading or a structural issue, prompting a priority inspection upon arrival.

- Light Sensors: A simple yet powerful tool, these sensors detect when a container’s doors are opened. This provides an indisputable record of unauthorized access or breaches in the cold chain.

The true power of this technology lies in its integration. The data streams from these sensors can be fed directly into your existing Transportation Management System (TMS). This allows you to move from a reactive to a predictive maintenance model. For example, if a specific container consistently reports high humidity on a certain route, it can be flagged for gasket replacement or retired from that lane. This data-driven approach provides an unprecedented level of control and oversight over your entire fleet, turning a low-cost investment into a powerful risk management tool.

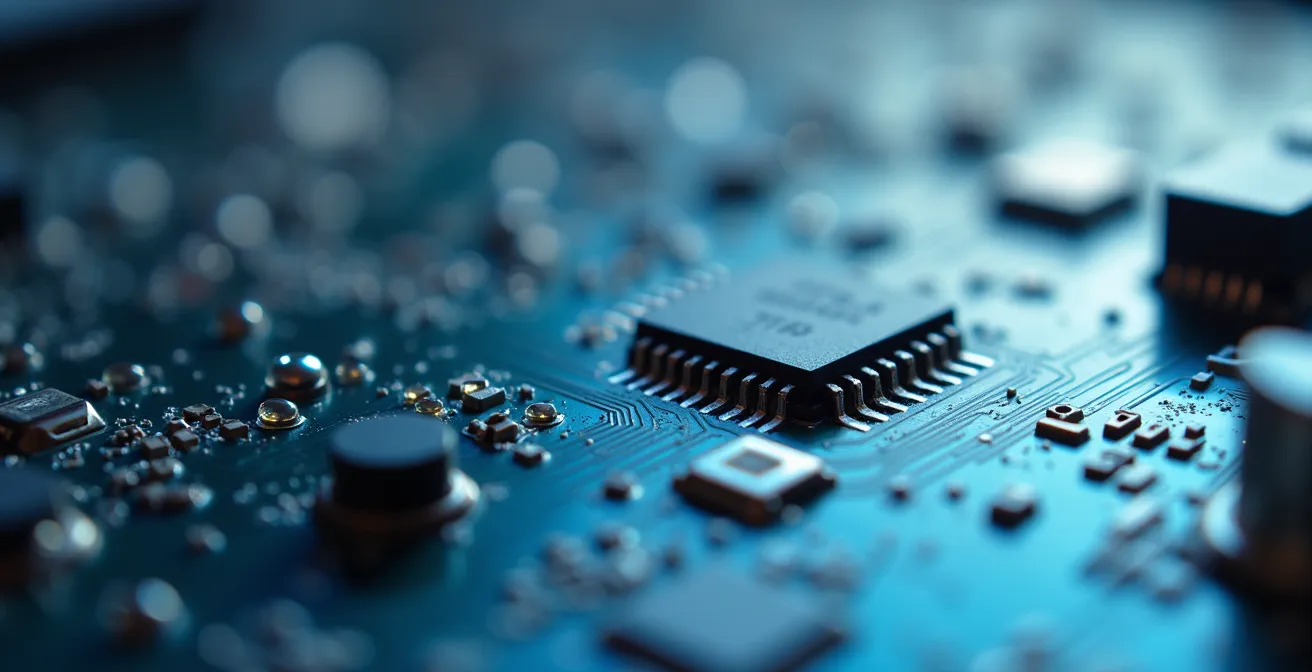

How to Mitigate Transloading Risks When Moving Fragile Electronics from Ocean to Rail?

One of the most vulnerable points in a supply chain is the transloading hub, where cargo is moved from one mode of transport to another—for example, from an ocean container to a domestic railcar. For fragile electronics, this process is fraught with risk, primarily from atmospheric shock. When a container that has been in a stable, cool environment on a ship is opened in a warm, humid port, the rapid change in conditions can be devastating. As warmer air, capable of holding more moisture, rushes in and hits the cooler surfaces of the electronics, condensation forms instantly. This can short-circuit components and cause irreparable damage.

The method of transfer is critical in mitigating this risk. Standard cross-docking, where pallets are moved from one container to another across an open dock, is the fastest but also the most dangerous method. It exposes the cargo to ambient conditions for a prolonged period, maximizing the risk of both atmospheric and physical shock. A safer, though slower, alternative is an intact intermodal transfer, where the entire ocean container is simply lifted onto a rail chassis. This keeps the container’s internal environment sealed and protected.

For the most sensitive electronics, a climate-controlled transfer facility is the optimal solution. These facilities allow the container to acclimatize to the local temperature gradually before being opened, minimizing the dew point differential that causes condensation. The choice of method involves a trade-off between speed, cost, and risk, which must be carefully evaluated. An analysis of intermodal transfer methods clearly highlights these differences.

| Method | Speed | Water Damage Risk | Atmospheric Shock Risk |

|---|---|---|---|

| Cross-docking (pallet-to-pallet) | Faster (2-4 hours) | High exposure during transfer | Maximum exposure to ambient conditions |

| Intact Intermodal | Slower (6-8 hours) | Minimal if container sealed | Protected from direct exposure |

| Climate-controlled transfer | Moderate (4-6 hours) | Low with proper facility | Minimal with acclimatization period |

How to Deploy IoT Sensors on Pallets to Eliminate Lost Inventory?

While container-level IoT provides a macro view of the cargo’s environment, pallet-level sensing offers a revolutionary leap in granularity and control. By attaching small, low-cost sensors to individual pallets, you can create a detailed, three-dimensional map of the conditions inside the container. This approach moves beyond simply knowing if the container is compromised; it tells you exactly *where* the problem is, often before it affects the entire shipment.

This technology is particularly effective at pinpointing localized failures. For example, a moisture spike detected by a sensor on a pallet in the front-right corner of a container is a strong indicator of a localized door gasket failure. Without pallet-level data, this small leak might go unnoticed until a significant portion of the cargo is damaged. As field testing demonstrates that deploying as few as 20 pallet sensors can create a 3D environmental map with up to 95% accuracy, giving supervisors a powerful diagnostic tool.

The deployment protocol is a critical part of a successful implementation. A best-practice approach involves these key steps:

- Assign Unique Identifiers: Each Bluetooth Low Energy (BLE) sensor on a pallet must have a unique ID, linking it to the specific product on that pallet.

- Establish a Gateway: A single gateway device at the container level aggregates data from all pallet sensors and transmits it to the cloud.

- Set Geofence Parameters: Geofencing alerts can be configured to trigger an alarm if a pallet is separated from its designated container, preventing theft or misplacement during transloading.

- Visualize Data: The sensor data should be fed into a dashboard that visualizes temperature and humidity gradients across the container, making it easy to spot anomalies.

- Program Automated Alerts: Set up automatic alerts for localized events, such as a sudden temperature drop or moisture spike on a single pallet, indicating a precise point of failure.

This level of granular monitoring transforms inventory management. It not only prevents widespread damage by enabling early intervention but also provides irrefutable evidence for insurance claims and helps identify recurring issues with specific containers or loading procedures. It’s the ultimate tool for eliminating blind spots in your supply chain.

Key Takeaways

- A “cargo worthy” designation is a minimum structural standard, not a guarantee of fitness for sensitive goods; “container sweat” is the true enemy.

- Owning your containers (SOC) or managing them via a master lease provides critical control over maintenance, quality, and inspection frequency.

- From weight distribution to intermodal transfers, a professional protocol must account for physical and atmospheric stresses throughout the entire transit lifecycle.

How to Move Heavy Bulk Commodities Safely Across Unstable Geopolitical Regions?

Shipping through unstable geopolitical regions introduces risks that transcend standard operational concerns: piracy, seizure, and unpredictable port closures. In these high-stakes environments, a conventional risk management approach focused on using the newest, highest-quality containers can be counter-productive. The risk of losing a high-value asset often outweighs the operational benefits it provides. An advanced, and somewhat counter-intuitive, strategy is required.

For these high-risk routes, the focus shifts from preventing damage to minimizing financial loss. As the Marine Risk Management Institute highlights in its guidelines, this often means using assets you can afford to lose. This is a powerful expert insight:

For high-risk routes, using older, fully-depreciated Shipper Owned Containers that you can afford to lose is more cost-effective than risking new, high-spec Carrier Owned Containers which could incur heavy penalties if lost or damaged.

– Marine Risk Management Institute, 2024 High-Risk Transit Guidelines

This strategy is coupled with “container hardening.” Rather than relying on a standard unit, shippers deploy security-enhanced containers. These units are outfitted with high-security barrier seals, reinforced locking mechanisms, and covert GPS trackers that provide real-time alerts for any deviation from the planned route. This combination of using a low-value container with high-value security features creates a resilient and financially sound solution. Case studies on their deployment in conflict zones show that these hardened containers can reduce loss rates by as much as 40% and often qualify for reduced war risk insurance premiums.

In essence, the strategy is to make the container itself an unattractive target while making the cargo inside extremely difficult to access or divert without detection. It is a pragmatic approach that accepts the reality of the operating environment and prioritizes loss mitigation over theoretical perfection.

By shifting from a reactive, visual-only inspection to a proactive, data-driven lifecycle assessment, you transform your container fleet from a liability into a controlled and reliable asset. Implementing these advanced protocols is the definitive next step to safeguarding your high-value goods against all forms of damage.